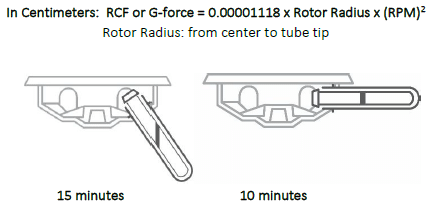

Fixed bucket rotors allow shorter sedimentation times in comparison to swing bucket rotors as higher rotational speeds and higher centrifugal forces can be achieved.

Swing bucket centrifuge vs fixed angle.

Lightweight alternative to conventional 250 rotors.

Fixed angle rotors are used for sedimentation with high centrifugal forces of up to and more than 60 000 x g typically needed in research laboratories.

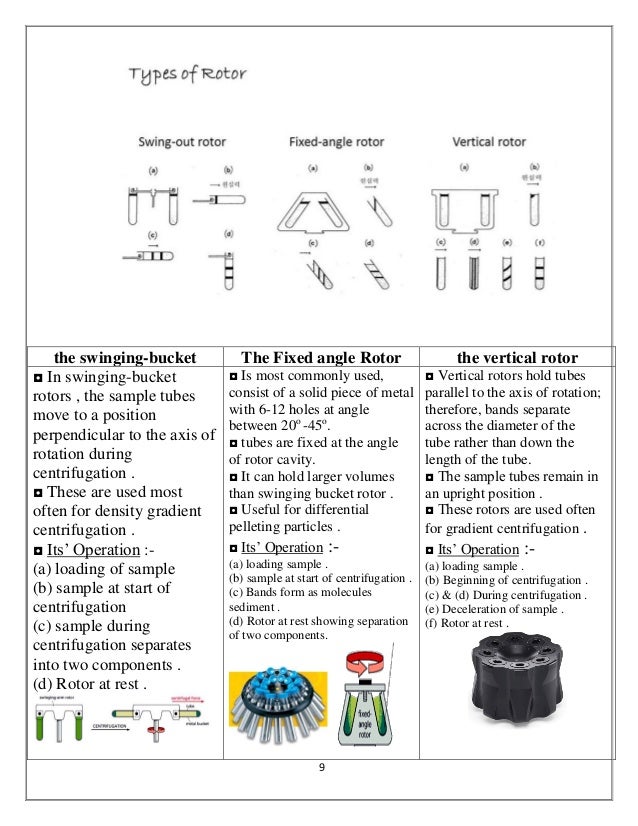

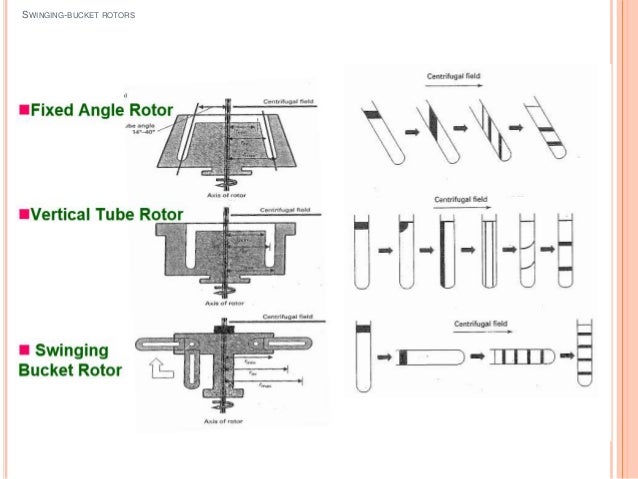

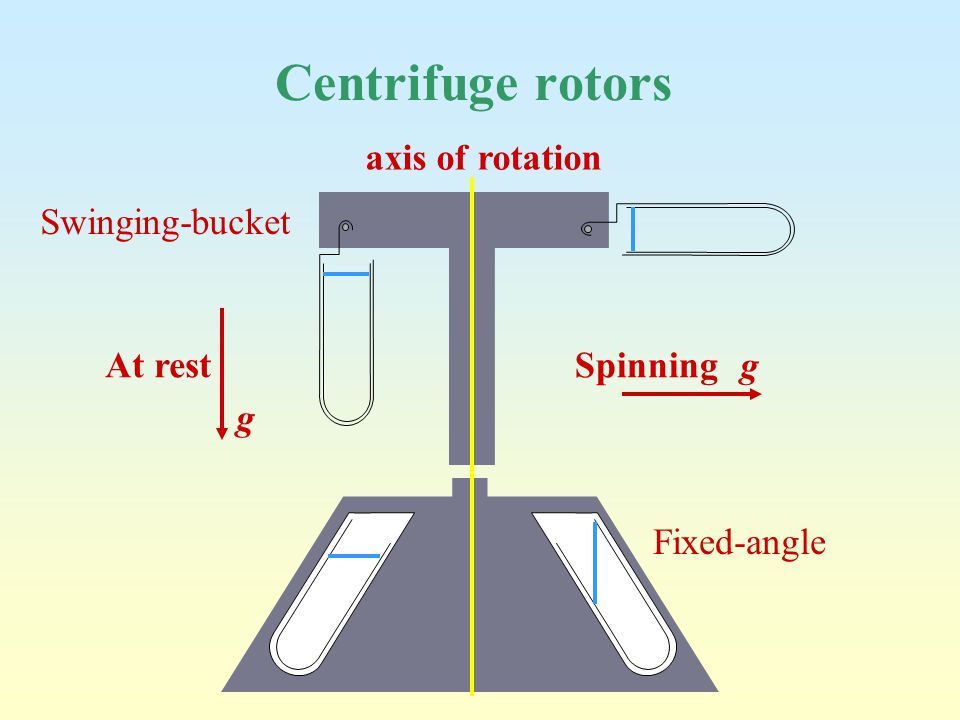

A swinging bucket rotor swings out when centripetal force is applied and holds the cells at an approximate 90 angle relative to the angle of rotation.

Fixed angle rotors hold tubes at a stable angle typically 45 relative to the axis of rotation.

When it comes to centrifuge rotors there are a couple basic types that you will need to choose between swing out and fixed angle.

Fixed angle or swinging bucket.

Fixed angle or swinging bucket.

Empty rotor weight is 10 3 kg 22 7 lb.

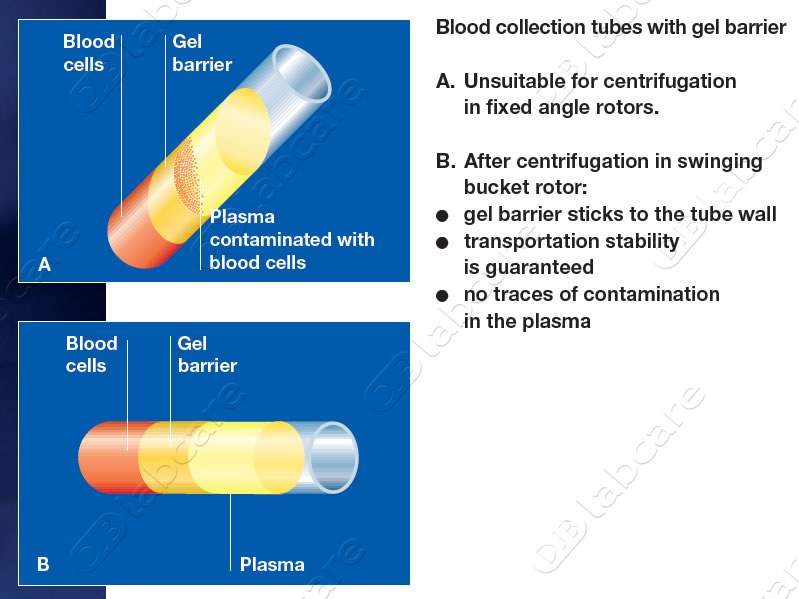

2 the sample divided with the use of the fixed angle rotor.

The sample divided with the use of the swing out bucket rotor.

The advantage of fixed angle rotors is that they don t have moving parts like swing bucket rotors.

When the rotor begins to rotate the solution in the tubes.

Fixed angle rotors hold tubes at a stable angle typically 45 relative to the axis of rotation.

There are two very common rotor designs.

Greater separation of liquids which contain larger solids separation of waste slurry or sand sized particles.

This results in higher possible g forces and thus shorter centrifugation times.

There are two main types of centrifuge rotors.

The centrifuge is composed of a rotor which is used to house the tubes where separation occurs.

The jla 16 250 fixed angle rotor with single lock lid is aluminum.

The fixed angle rotor is designed to hold tubes in a fixed position at a fixed angle relative to the vertical axis of rotation up to about 45.

Fixed angle rotors are therefore exposed to much lower metal stress than swing bucket rotors.

The rotor is used in avanti j series and j2 series centrifuges.

Fixed angle rotor is the rotor which holds tubes in the exact same fixed angle all the time usually 45 degrees.

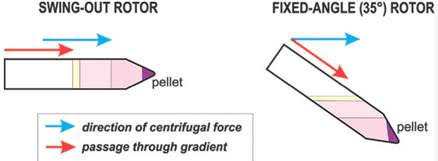

Therefore in swinging bucket rotors the pelleted material will form at the bottom of the conical centrifuge tube whereas tubes processed in a fixed angle rotor will form sedimentation on the side.

Centrifugation will cause particles to sediment along the side and bottom of the tube.

There are two main types of centrifuge rotors.

Benefits of a swing out bucket rotor.

It is clearly visible that precipitate is located in the center of the tube.

In case of using fixed angle rotor the direction of separation is 45 degrees relative to the axis of rotation.

Fixed angle and swinging bucket.

As the name indicates a fixed angle rotor holds tubes at a fixed angle usually 45.